GRP (Glass Reinforced Plastic) pipe seals and gaskets are critical components used in the installation and maintenance of GRP pipelines. GRP pipes, also known as fiberglass-reinforced plastic pipes, are commonly used in various industries for their corrosion resistance, durability, and lightweight properties. The seals and gaskets for GRP pipes play a crucial role in ensuring the integrity and reliability of these pipelines. Here’s more information about GRP pipe seals and gaskets:

1. Material Selection:

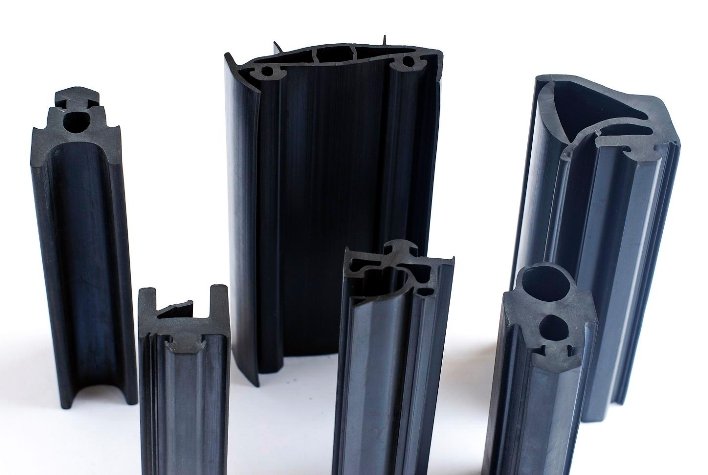

- GRP pipe seals and gaskets are typically made from elastomeric materials such as EPDM, neoprene, or nitrile rubber. These materials are chosen for their resistance to water, chemicals, and environmental factors.

2. Sealing Function:

- GRP pipe seals and gaskets are designed to create a watertight and airtight seal between pipe joints, connectors, and other pipe components. This prevents leaks and ensures the efficient transport of fluids.

3. Compression and Resilience:

- These seals and gaskets are designed to be compressed between pipe joints. They possess the resilience to maintain a tight seal even when exposed to pressure fluctuations, temperature variations, or ground movement.

4. Corrosion Resistance:

- GRP pipe seals and gaskets are resistant to corrosion, making them suitable for use in both underground and above-ground applications. They do not deteriorate when exposed to soil, water, or aggressive chemicals.

5. Customization:

- GRP pipe seals and gaskets can be custom-engineered to fit specific pipe diameters and configurations. This ensures a precise and secure fit, minimizing the risk of leaks.

6. Easy Installation:

- Installing GRP pipe seals and gaskets is typically straightforward and requires minimal tools. This ease of installation contributes to cost-effectiveness during pipeline construction and maintenance.

7. Durability:

- These seals and gaskets are designed for long-term durability, reducing the need for frequent replacements and maintenance. This durability is particularly advantageous in buried or hard-to-reach pipeline systems.

8. Resistance to UV and Environmental Factors:

- Some GRP pipe seals and gaskets are engineered to withstand exposure to UV radiation and harsh environmental conditions, ensuring they maintain their sealing properties over time.

9. Application Areas:

- GRP pipe seals and gaskets are used in a wide range of applications, including water and wastewater systems, chemical processing plants, oil and gas pipelines, marine installations, and more.

10. Compliance and Testing:

– These seals and gaskets are often subject to stringent quality control and testing procedures to ensure they meet industry standards and regulatory requirements.

In summary, GRP pipe seals and gaskets are essential components that help maintain the efficiency and reliability of GRP pipeline systems. Their ability to create a secure and durable seal at pipe joints is critical for preventing leaks and ensuring the safe transport of fluids in various industrial and infrastructure applications.