Dilatation seals, also known as expansion joints or expansion seals, are specialized mechanical devices designed to accommodate the thermal expansion and contraction of various structures, such as pipelines, bridges, buildings, and industrial equipment. These seals are essential components in many engineering and construction projects, as they help to prevent damage and maintain the integrity of these structures by allowing them to flex and adapt to changing environmental conditions.

Here’s a detailed description of dilatation seals:

- Purpose:

Dilatation seals serve the primary purpose of absorbing and compensating for the movements caused by temperature variations, vibrations, and settling, which can occur in structures and systems. By doing so, they help to reduce stress and maintain the structural integrity of the components they are installed in. - Types:

Dilatation seals come in various forms to suit different applications. Some common types include:

- Expansion Joints: Used in pipelines and duct systems to absorb linear expansion and contraction.

- Isolation Joints: Isolate different sections of a structure, preventing the transmission of forces and vibrations.

- Bridge Expansion Joints: Installed in bridges to absorb movements caused by traffic, temperature fluctuations, and ground settlement.

- Building Expansion Joints: Used in construction to allow for the expansion and contraction of building materials.

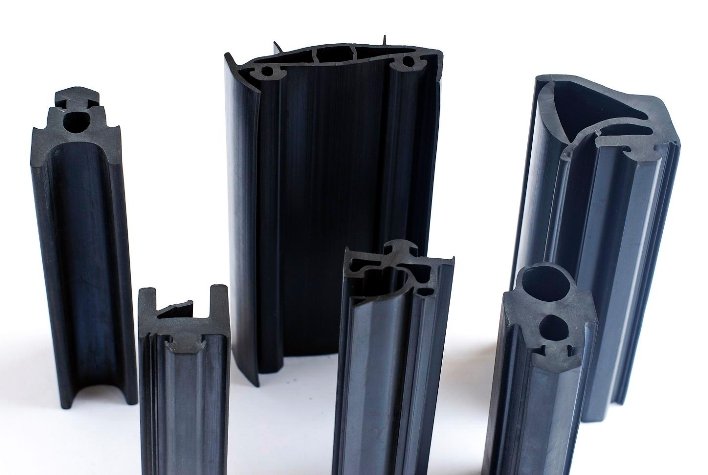

- Rubber and Metal Bellows: Flexible, accordion-like structures that accommodate movement in pipes and industrial equipment.

- Materials:

Dilatation seals are typically made from materials that are resistant to wear, corrosion, and temperature fluctuations. Common materials include:

- Rubber: Often used for smaller applications, such as in buildings and pipelines.

- Metal: Stainless steel, aluminum, and other metals are used for heavy-duty industrial applications.

- Fabric: Reinforced fabric expansion joints are used in gas and air duct systems.

- Installation:

The installation of dilatation seals requires careful planning and engineering. They are typically integrated into the structure during the construction phase. The design should consider factors like the expected range of movement, temperature fluctuations, and the specific environment where they will be used. - Maintenance:

Proper maintenance is crucial to ensure the long-term functionality of dilatation seals. This includes regular inspections to check for signs of wear, damage, or displacement. Any issues should be promptly addressed to prevent further damage to the structure. - Benefits:

Dilatation seals offer several advantages, including:

- Enhanced structural integrity: They prevent structural damage caused by thermal expansion and contraction.

- Extended service life: Dilatation seals help prolong the lifespan of structures and equipment.

- Safety: By reducing stress and preventing leaks or failures, they contribute to overall safety.

- Improved efficiency: In industrial applications, they help maintain operational efficiency.

- Applications:

Dilatation seals are used in a wide range of industries, including construction, transportation, petrochemical, power generation, and manufacturing. They are found in pipelines, bridges, buildings, industrial machinery, and more.

In summary, dilatation seals are crucial components in various engineering and construction projects, serving to accommodate structural movements and temperature changes. They come in different forms and materials, are installed during construction, and require regular maintenance to ensure their effectiveness in preserving the integrity and safety of structures and systems.