Aluminum rubber seals, also known as aluminum rubber gaskets or aluminum rubber seals, are essential components used in various industrial and automotive applications to provide a reliable and effective barrier against the ingress of liquids, gases, dust, and contaminants. These seals are meticulously engineered to meet specific performance requirements and are highly valued for their versatility, durability, and resistance to environmental factors.

Composition:

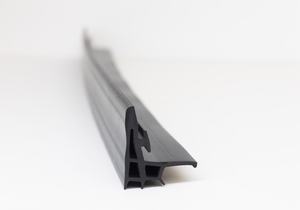

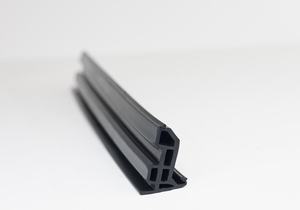

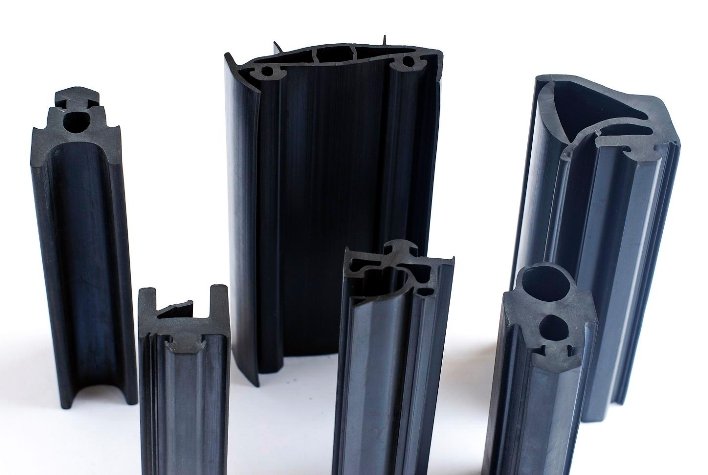

Aluminum rubber seals typically consist of two primary components: an aluminum core or carrier and a rubber elastomer. The choice of rubber elastomer can vary depending on the intended application, with common options including silicone rubber, EPDM (ethylene propylene diene monomer) rubber, neoprene rubber, or nitrile rubber. The combination of these materials creates a sealing solution that capitalizes on the best properties of both aluminum and rubber.

Key Features and Benefits:

- Excellent Sealing Properties: Aluminum rubber seals excel in forming airtight and watertight seals, making them invaluable for applications where leak prevention is critical, such as in automotive engines, HVAC systems, and hydraulic systems.

- Durability: These seals are designed to withstand a wide range of temperatures, pressures, and environmental conditions. They resist degradation from exposure to UV radiation, ozone, and harsh chemicals.

- Corrosion Resistance: The aluminum core of these seals provides exceptional resistance to corrosion, making them ideal for use in outdoor and marine applications.

- Vibration and Shock Absorption: The rubber component of the seals helps dampen vibrations and absorb shocks, preventing damage to sensitive equipment and ensuring a longer service life.

- Customization: Aluminum rubber seals can be custom-engineered to meet specific design and performance requirements. This includes variations in size, shape, thickness, and hardness to suit various sealing applications.

- Easy Installation: They are relatively easy to install, often requiring minimal tools and equipment, which contributes to cost-effectiveness in manufacturing and maintenance processes.

Applications:

Aluminum rubber seals find application across a wide spectrum of industries, including:

- Automotive: They are used in engines, transmissions, doors, windows, and various automotive systems to prevent fluid leaks and reduce noise and vibration.

- Aerospace: These seals are employed in aircraft components to ensure airtight and watertight seals and to withstand extreme environmental conditions.

- Construction: They are used in doors, windows, and roofing systems to enhance insulation, weatherproofing, and noise reduction.

- Industrial Machinery: They play a crucial role in sealing pumps, valves, and other machinery to prevent leaks and contamination.

- Marine: Aluminum rubber seals are used in boat and ship components to protect against water intrusion and corrosion.

- HVAC (Heating, Ventilation, and Air Conditioning): They provide effective sealing solutions in HVAC systems to maintain temperature control and prevent air and moisture leakage.

- Electronics: In electronics enclosures, these seals protect sensitive equipment from dust, moisture, and electromagnetic interference.

Conclusion:

Aluminum rubber seals represent a sophisticated engineering solution that combines the strengths of aluminum and rubber materials to provide outstanding sealing performance, durability, and versatility across numerous industries. Their ability to maintain effective seals in challenging environments makes them an indispensable component in modern manufacturing and engineering applications. Whether it’s in a high-performance car engine or a critical aerospace component, aluminum rubber seals play a pivotal role in ensuring the integrity and longevity of various systems and equipment.