EPDM (Ethylene Propylene Diene Monomer) rubber gaskets are widely used sealing components known for their excellent resistance to weathering, ozone, UV radiation, moisture, and a wide range of chemicals. These gaskets are versatile and are commonly employed in various industries for sealing applications where durability and environmental resistance are essential. Here’s more information about EPDM rubber gaskets:

1. Material Characteristics:

- Weather Resistance: EPDM rubber is well-known for its exceptional resistance to outdoor weathering, making it suitable for outdoor applications where exposure to sunlight, rain, and temperature variations is common.

- Chemical Resistance: EPDM exhibits resistance to a variety of chemicals, including acids, bases, and many solvents. This chemical resistance contributes to its durability in various environments.

- UV Stability: EPDM retains its properties and does not degrade when exposed to ultraviolet (UV) radiation, making it ideal for outdoor applications.

- Moisture Resistance: EPDM gaskets are effective in preventing the ingress of moisture and are often used in applications where a watertight seal is required.

2. Sealing Applications:

EPDM rubber gaskets find applications in a wide range of industries and settings, including:

- Automotive: EPDM gaskets are used in the automotive industry for sealing engine components, doors, windows, and other critical areas. They provide a watertight and weatherproof seal.

- Construction: EPDM gaskets are used in the construction industry for sealing windows, doors, roofing systems, and HVAC ductwork. They offer both thermal insulation and weather resistance.

- Electronics: EPDM gaskets are employed in electronics enclosures to provide environmental sealing, protecting sensitive components from moisture and dust.

- HVAC (Heating, Ventilation, and Air Conditioning): EPDM gaskets are used in HVAC systems to create airtight seals in ductwork and equipment, ensuring energy efficiency and preventing air leakage.

- Marine: EPDM gaskets are used in marine applications to seal hatches, ports, and other openings to prevent water ingress.

- Industrial Equipment: They are used in various industrial equipment and machinery to provide seals against dust, moisture, and environmental contaminants.

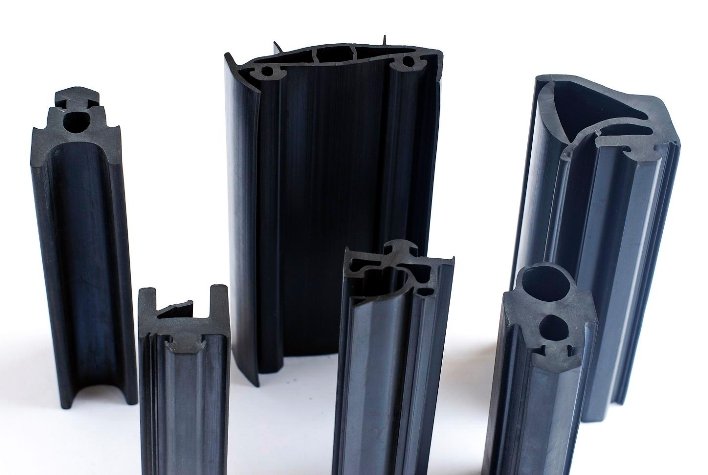

3. Customization:

EPDM rubber gaskets can be custom-designed and manufactured to meet specific application requirements. They come in various shapes, sizes, and thicknesses to fit different sealing needs.

4. Installation:

Installing EPDM rubber gaskets typically involves placing them between two mating surfaces, such as a door and its frame, and then compressing them to create a seal.

5. Maintenance:

Regular inspection and maintenance of EPDM rubber gaskets are essential to ensure their continued effectiveness. Over time, gaskets may need replacement if they show signs of wear or damage.

In summary, EPDM rubber gaskets are versatile sealing components known for their outstanding weather resistance, chemical resistance, and durability. They play a crucial role in creating effective seals in a wide range of applications across various industries, contributing to the efficiency, longevity, and reliability of systems and equipment.