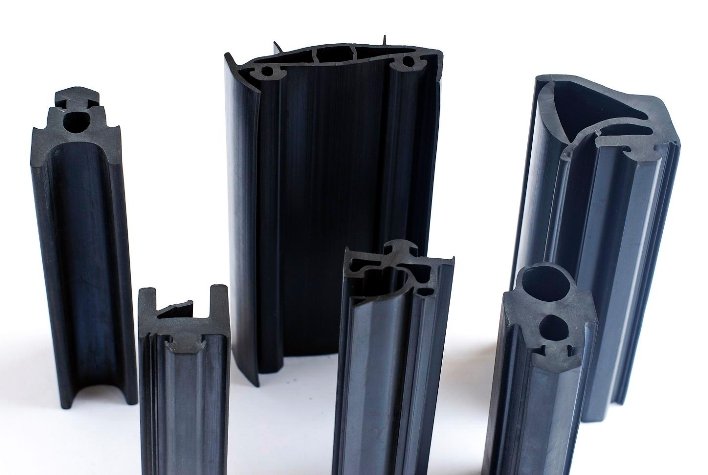

Aluminum rubber seals, also known as aluminum rubber gaskets or aluminum rubber profiles, are specialized sealing components that combine the properties of aluminum and rubber to create an effective sealing solution. These seals are used in various applications where a reliable and durable seal is required, along with the benefits of both aluminum and rubber materials. Here’s more information about aluminum rubber seals:

1. Composition:

- Aluminum rubber seals typically consist of an aluminum core or frame surrounded by a layer of rubber or elastomeric material. This combination provides the advantages of both materials.

2. Key Features:

- Sealing Properties: The rubber or elastomeric portion of the seal provides excellent sealing properties. It can effectively block the passage of liquids, gases, dust, and other contaminants, making it suitable for sealing applications.

- Aluminum Structure: The aluminum core or frame adds structural strength and rigidity to the seal. This can be important in applications where mechanical strength and support are required.

- Durability: Aluminum is corrosion-resistant and can withstand exposure to outdoor elements and harsh environmental conditions. The rubber portion of the seal is often designed to resist wear, UV radiation, and temperature fluctuations.

- Vibration and Impact Absorption: Rubber has excellent vibration and impact absorption properties. Aluminum rubber seals can dampen vibrations and provide cushioning, making them suitable for applications where shock absorption is necessary.

- Customization: Aluminum rubber seals can be customized in terms of shape, size, and material selection to meet specific application requirements.

3. Applications:

- Automotive Industry: Aluminum rubber seals are commonly used in the automotive industry for sealing various components, including doors, windows, hoods, trunks, and engine compartments.

- Construction and Architecture: They are used in doors, windows, and curtain wall systems to provide weatherproofing and insulation.

- Industrial Equipment: Aluminum rubber seals find applications in machinery and equipment to prevent leaks, contamination, and provide sealing in harsh environments.

- Electrical Enclosures: These seals are used in electrical cabinets and enclosures to maintain environmental integrity and protect sensitive electronic components.

- Aerospace: In aerospace applications, aluminum rubber seals can be used in aircraft doors, windows, and other critical areas to ensure airtight seals and safety.

- Marine: They are suitable for marine applications, such as sealing hatches, doors, and windows on boats and ships.

4. Installation:

Installing aluminum rubber seals typically involves fitting the seal into the desired area or component, ensuring a secure and tight fit to achieve effective sealing.

5. Maintenance:

Regular inspection and maintenance may be necessary to ensure the seals remain in good condition, especially in applications exposed to extreme conditions.

In summary, aluminum rubber seals are versatile components that offer a combination of sealing efficiency, durability, and structural support. They are widely used in various industries and applications where a reliable seal is essential, and the seals must withstand challenging environmental conditions.