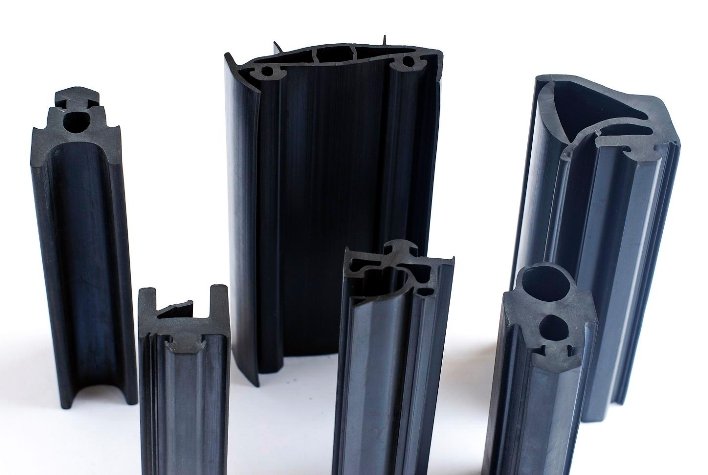

Certainly! A detailed description of an aluminum rubber seals factory provides insight into the processes, technologies, and operations involved in the production of these critical industrial components.

Factory Overview:

Location: The aluminum rubber seals factory is strategically located in an industrial zone with easy access to transportation networks for the efficient delivery of raw materials and distribution of finished products.

Facility Size: The factory encompasses a significant area, housing various departments and production lines to accommodate the diverse range of aluminum rubber seals manufactured.

Production Capacity: The factory boasts a robust production capacity capable of meeting the demands of both domestic and international markets. It operates on a multi-shift basis to maximize productivity.

Production Processes:

- Material Procurement: The heart of the manufacturing process begins with sourcing high-quality materials. Aluminum sheets and rubber elastomers are procured from trusted suppliers, ensuring compliance with industry standards.

- Material Preparation: Aluminum sheets are cut into specific shapes and sizes using advanced cutting machines. Rubber elastomers are processed to achieve the desired hardness and flexibility characteristics.

- Bonding: The aluminum sheets and rubber elastomers are meticulously bonded together using specialized adhesives and bonding techniques. This step requires precision to ensure a strong and durable bond.

- Die-Cutting: The composite material is then die-cut into the required shapes and sizes. Computer-controlled die-cutting machines ensure accuracy and consistency.

- Molding and Compression: Some seals may undergo molding and compression processes to achieve complex shapes and specific performance properties. Heat and pressure are applied to create the final seal configuration.

- Quality Control: At various stages of production, rigorous quality control checks are performed to ensure that each aluminum rubber seal meets the required specifications. This includes testing for dimensions, bonding strength, hardness, and material integrity.

- Surface Treatment: Surface treatments such as anodizing or coating may be applied to the aluminum side of the seals to enhance corrosion resistance and improve aesthetics.

- Packaging: Finished aluminum rubber seals are carefully packaged to protect them during storage and transportation. Packaging methods are optimized to accommodate different seal sizes and quantities.

Technological Advancements:

The factory leverages state-of-the-art technology to enhance efficiency and quality. This includes computer-aided design (CAD) software for precise seal design, CNC (computer numerical control) machinery for cutting and machining, and automated production lines for high-volume manufacturing.

Environmental Considerations:

The factory places a strong emphasis on environmental sustainability. Waste management systems are in place to recycle and minimize waste. Energy-efficient equipment and processes are utilized to reduce the factory’s carbon footprint.

Skilled Workforce:

A skilled and dedicated workforce is the backbone of the factory. Technicians, engineers, quality control experts, and production operators collaborate to ensure the seamless operation of the production process.

Research and Development:

The factory invests in ongoing research and development to innovate and improve seal designs, materials, and manufacturing processes. This commitment to innovation keeps the factory at the forefront of the industry.

Customer Focus:

Customer satisfaction is paramount. The factory maintains open lines of communication with customers to understand their specific requirements and deliver tailored solutions. Customization is a core capability, allowing the production of seals that meet unique application needs.

Certifications and Standards:

The factory adheres to international quality standards and certifications relevant to the industry, ensuring that its aluminum rubber seals meet or exceed customer expectations and industry regulations.

In summary, the aluminum rubber seals factory is a sophisticated manufacturing facility equipped with advanced technology, skilled personnel, and a commitment to quality and sustainability. Its production processes are designed to meet the diverse needs of various industries, providing essential sealing solutions that contribute to the reliability and efficiency of machinery and systems worldwide.